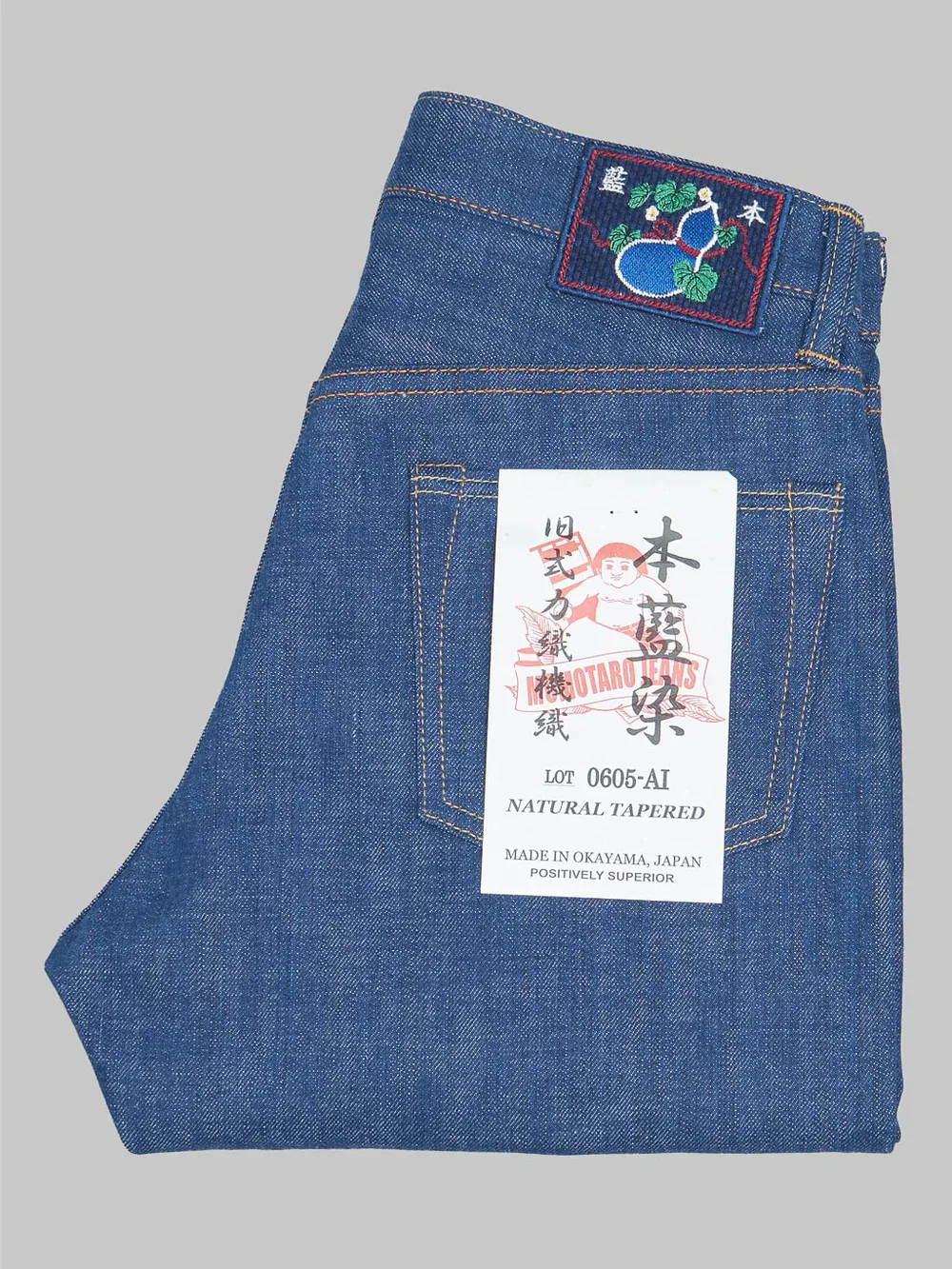

Here’s of the most exclusive, handcraftiest paira jeans you’ll ever see. Each represents the apex of craftsmanship, taking up to a year to produce in wicked limited quantities. Momotaro has dyed these lovelies with premium Japanese Natural Indigo from the 'Polygonum tinctorium' plant.

Oh hell ya.

Following traditional Japanese "Aizome" method, the leaves are naturally fermented for over 100 days without any chemicals.

Yes, gimme.

Once mature, cotton yarns are hand-dipped into the Indigo once a day for 30 days. Sign me up. All this work results in the rich, vibrant Indigo hues "Aizome" is renowned for. Each unit undergoes a meticulous hand-dying process, making every jean a one-of-a-kind masterpiece.

More Reasons to Snag These Grail-Worthy Jeans

Made from an extra-long staple, top-grade 13.5oz Zimbabwe Cotton grown especially indoors and hand-picked. This cotton is famous for its exceptional strength and softness that is similar to the finest Silk. The fabric is slowly woven on a first gen Toyoda GL9 shuttle loom. This vintage half-hand operated loom takes 5-7 days for a single pair of jeans. Because of this, each woven piece of fabric is only enough for 1 pair of jeans. Making each pair truly unique and one of a kind.

The patch is a hand-woven Natural Indigo Sashiko with exclusive hand-embroidered design. It depicts a magical gourd meant to catch evil spirits and bring good luck and life. The yoke lining is a luxurious Natural Indigo Silk for exceptional strength and comfort. The custom top fly button and hand-hammered rivets are 925 Silver. The Selvedge ID is a special Natural Indigo thread. And the pocket bags are a GL9 Zimbabwe Cotton with limited "Aizome" Momotaro print and Momotaro tab.

Some Things About Indigo As Your Brain Processes These Jeans

Indigo is purported to be the oldest dye used by humans worldwide, introduced to Japan around 1500 years ago. Originally it was considered a noble color predominantly worn by courts and upper aristocrats during the Heian period. It was during the Edo period that indigo spread among the common people, and it is said that kimonos, work clothes, shop curtains, and even bedclothes were gettin’ dyed in indigo. Revered by the Japanese as an “auspicious” color, indigo was the symbolic color of Japan during the Meiji era, referred to as "Japan Blue" in other countries.

Indigo dyeing in Tokushima is rumoured to have been introduced to Japan around 900 AD by the lord of Awa, Hachisuka, who recognized that the climate along the Yoshino River was suitable for indigo cultivation. The technique used in indigo dyeing in Tokushima is called "fermentation," with Awa indigo as a raw material. Since it cannot be dyed to a dark shade all at once, the process of dyeing, squeezing, and drying is repeated many times. It is said that the authentic color achieved through the Awa Shoai dyeing technique (hank dyeing) is obtained after washing with water about 30 times, during which the uneven color is washed off until a deep shade is achieved.

This method of creating indigo dye is labor-intensive and incredibly time-consuming. Leaves are carefully gathered from the indigo plant and placed under thick straw mats for months on end. To ensure the leaves ferment properly, very specific conditions must be consistently maintained. Workers must perform daily maintenance to ensure that the leaves have proper airflow and stay at a temperature around 60 degrees Fahrenheit.

From picking the leaves to completion, the entire fermentation process takes approximately one full year. Finally, after months of patience and dedicated work, the final result is something that resembles dirt, but with a pungent, vinegary aroma. This product, known as "sukumo," serves as the basis for indigo dye.

Just as the indigo dyers of hundreds of years ago, the "Aizome" dyeing is a manual process, done on hands and knees while leaning over a large metal vat of inky blue indigo dye. The shade of blue after one dip will be very light, and the dipping process must be repeated multiple times to achieve darker colors.

Momotaro

Momotaro is a Japanese denim brand that was founded in Kojima, Okayama in 2005. The brand's philosophy is centered around the concept of "Made by Hand Without Compromise", which reflects their commitment to using traditional techniques and high-quality materials to create their products. They work with skilled craftsmen in Kojima to produce their denim, and place a strong emphasis on attention to detail and quality control.

These mindbenders are available at Red Cast Heritage.